The installation location and orientation of an ultrasonic level transmitter can significantly impact its accuracy and reliability. Here are several key considerations:

Obstacle Avoidance: Conduct a comprehensive site survey to identify potential obstacles, including pipes, supports, or other structures that may interfere with the ultrasonic signal path. Implement physical barriers or reflective shields strategically to minimize signal reflections and enhance measurement accuracy. Regularly assess the surrounding environment for changes that could impact signal integrity.

Mounting Height: Precisely determine the mounting height above the liquid or solid surface by considering the specific beam angle characteristics of the ultrasonic transducer. Account for variations in surface conditions and establish a height that optimizes signal penetration and minimizes the risk of signal loss due to excessive distances. Regularly review and recalibrate mounting heights based on changes in operational conditions.

Vessel Shape and Size: Tailor the ultrasonic level transmitter configuration to accommodate the geometric intricacies of the vessel. For irregularly shaped vessels, employ advanced signal processing algorithms to compensate for non-uniform reflections. Implement specialized transducer designs for small containers, ensuring that the system adapts to diverse vessel characteristics. Conduct periodic assessments to account for changes in vessel geometry.

Material Compatibility: Conduct thorough acoustic testing of vessel materials and the substance being measured. Utilize transducer frequencies and configurations that align with the acoustic characteristics of specific materials. Implement real-time adjustments or adaptive algorithms to account for changes in material properties over time. Stay abreast of advancements in material science to optimize measurement accuracy.

Temperature Considerations: Employ temperature compensation algorithms that dynamically adjust for variations in sound velocity due to temperature changes. Install temperature sensors in close proximity to the transducer to provide real-time data for accurate compensation. Implement insulation or environmental controls to minimize the impact of extreme temperatures on the ultrasonic signal. Regularly validate and update temperature compensation algorithms.

Wind and Atmospheric Conditions: Conduct a thorough analysis of wind patterns and atmospheric conditions at the installation site. Design and install physical barriers, windbreaks, or shields to mitigate the impact of wind-induced disturbances. Implement predictive modeling or real-time monitoring to dynamically adjust for atmospheric conditions that could influence signal propagation. Regularly update and refine strategies based on ongoing environmental assessments.

Surface Conditions: Utilize advanced signal processing techniques, such as frequency modulation or signal filtering, to differentiate between genuine level changes and surface disturbances like turbulence or foam. Implement adaptive algorithms that can dynamically adjust parameters based on changing surface conditions. Regularly review and optimize signal processing parameters to maintain accuracy under diverse surface scenarios.

Orientation: Enforce strict adherence to manufacturer guidelines for transducer alignment with the liquid or solid surface. Implement precision calibration routines that include checks for transducer orientation. Utilize monitoring systems to alert operators to any deviations in transducer alignment and enable prompt corrective actions. Conduct regular calibration audits to ensure ongoing alignment accuracy.

Calibration and Configuration: Establish a comprehensive calibration schedule that includes routine checks and recalibrations based on environmental changes or equipment aging. Implement automated calibration processes where feasible to minimize human error. Document calibration procedures and maintain a detailed calibration history for auditing purposes. Regularly review and update calibration protocols in response to changing operational requirements.

Maintenance Accessibility: Design installation layouts that prioritize easy access for maintenance activities. Clearly define access points, and implement modular components that facilitate quick disassembly for cleaning, inspection, or repairs. Develop a proactive maintenance schedule that includes regular equipment checks, cleaning procedures, and component replacements as necessary. Conduct regular reviews of maintenance accessibility to identify and address potential improvements.

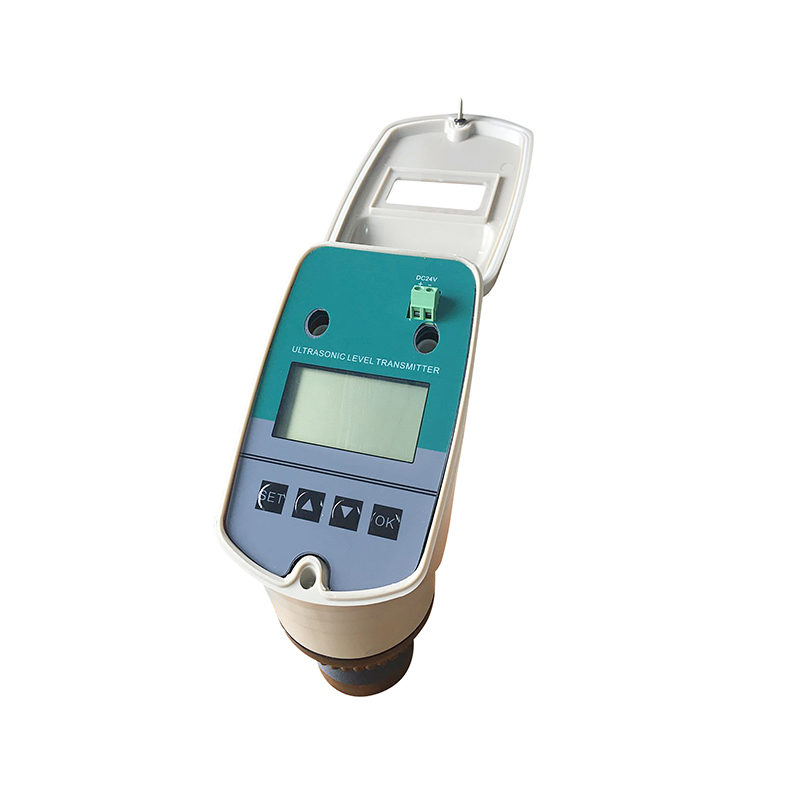

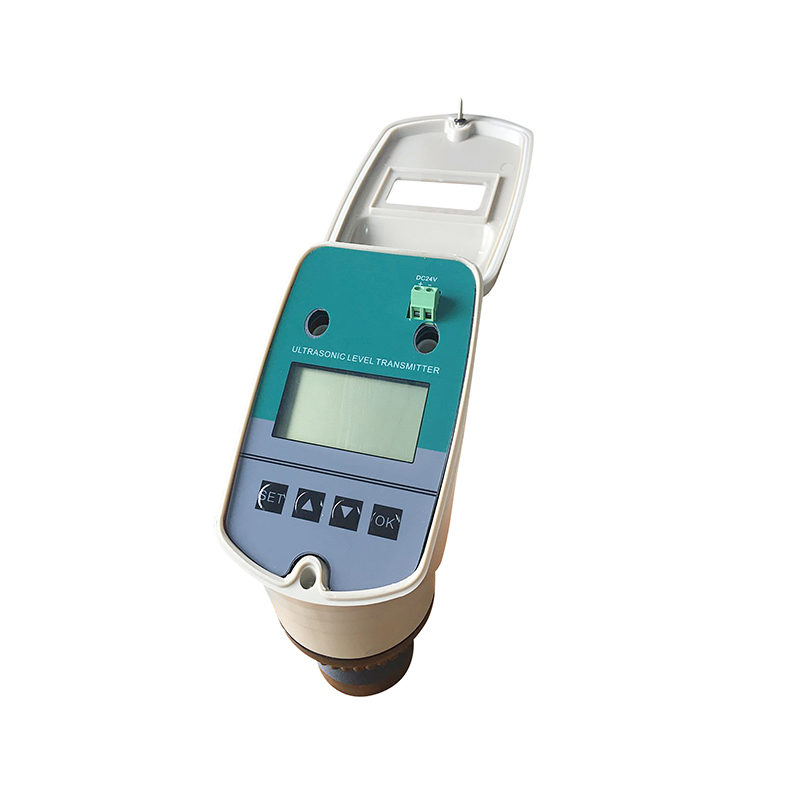

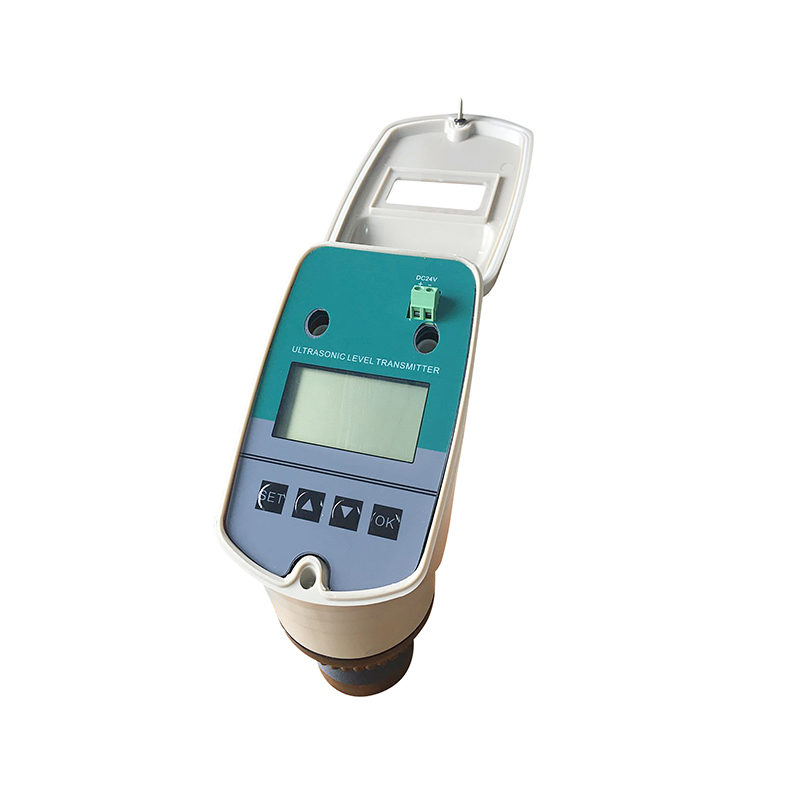

Ultrasonic level transmitter 2